The stations

The SMARTtray® Workflow

Sowing the seed

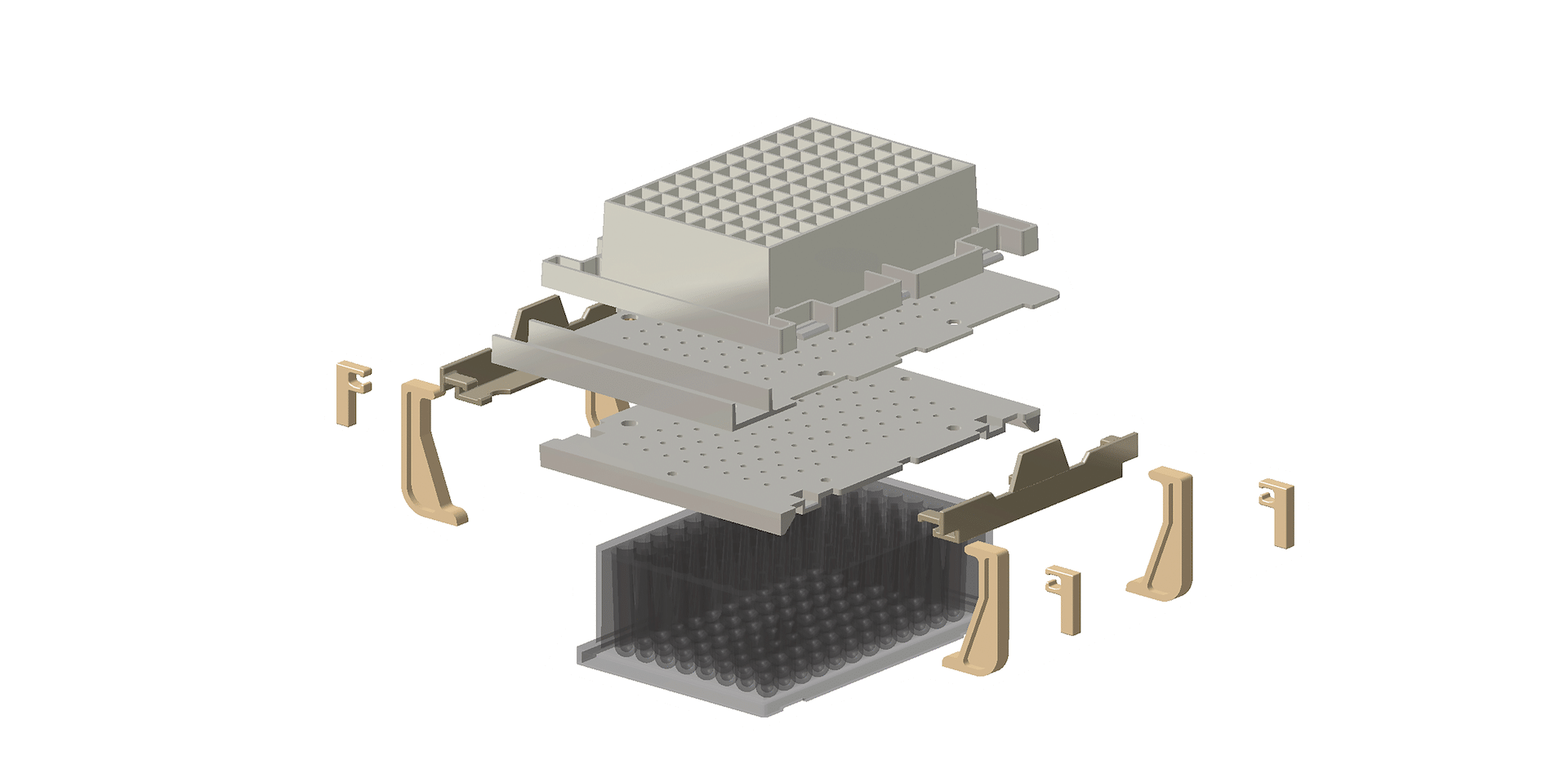

The cultivation plate is filled with a substrate. A vacuum seed dispenser is used to place the seed in the individual wells of the cultivation plate. The roots of the plants grow through the bottom openings, the cutting wells and the openings of the cutting plate into the matching sample containers.

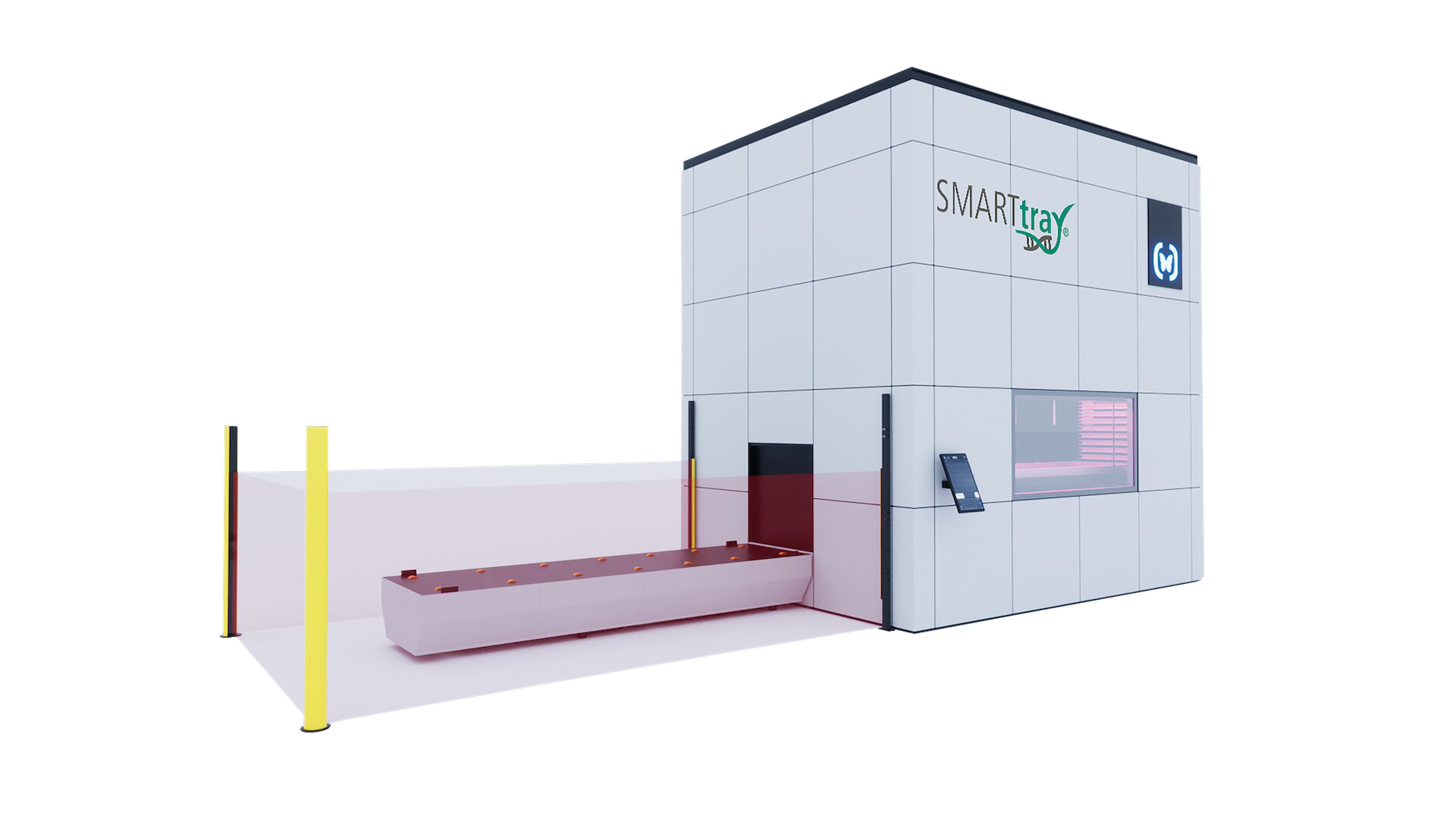

Cultivation

The plants are cultivated automatically under controlled conditions. LEDs enable precise control of root and shoot growth at the relevant stage.

Sampling

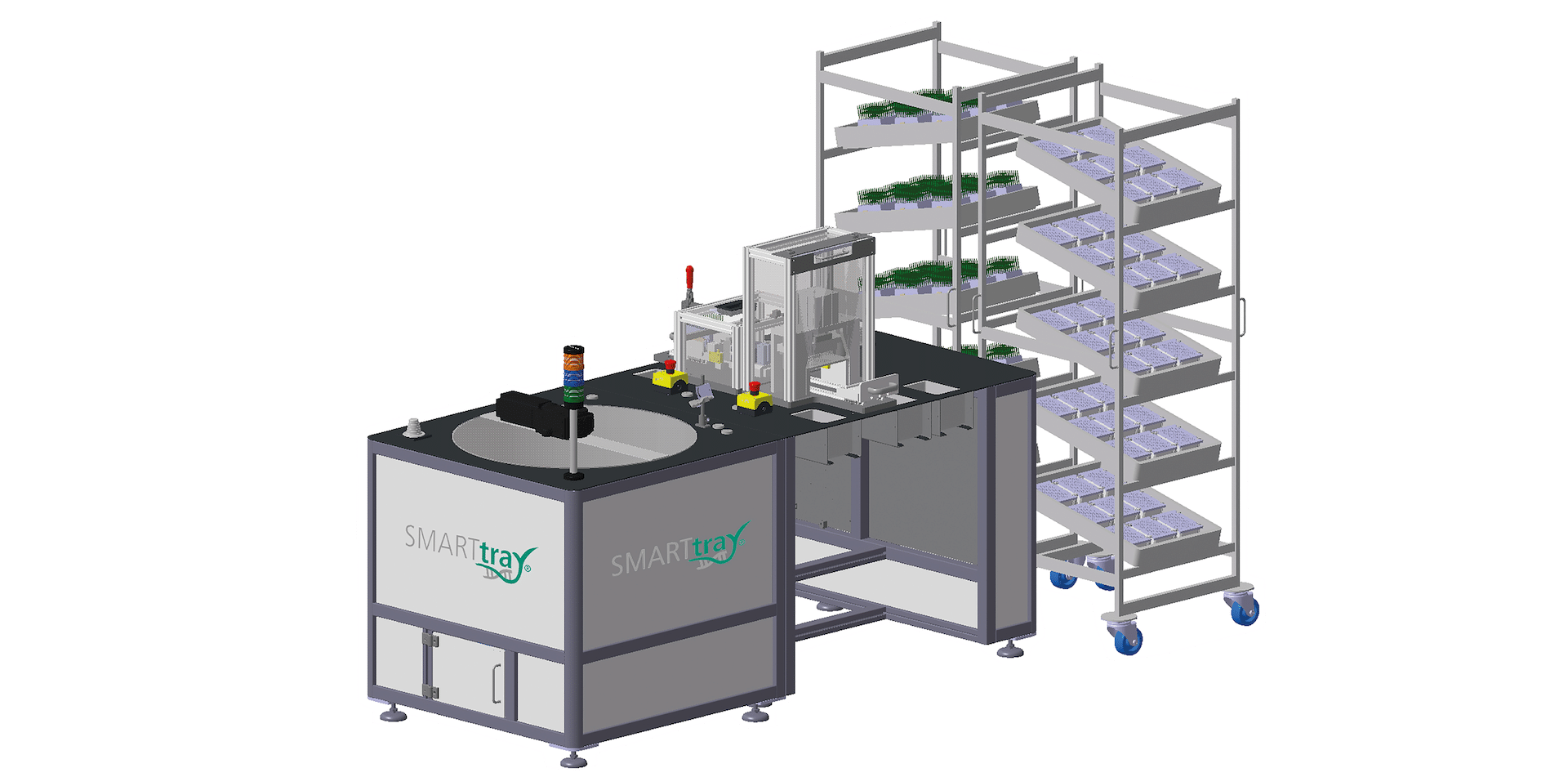

As soon as the plants have developed sufficient root mass in the sample container, a cutting machine samples the roots with the cutter integrated in the device without damaging the development of the plant.

Dewatering

Punching

The punching unit ensures contamination-free removal of the cutter and cutting plate from the sample container.

Continuous Cultivation

The intact plants remain in the cultivation plate and are then returned to the cultivation unit, while the removed root tissue is transferred to the laboratory for DNA extraction and marker-assisted selection (MAS).

DNA extraction

Depending on the application, different and scalable DNA extraction methods are used.

Marker-Assisted-Selection (MAS)

Selection of plants

Only the plants with the desired genetic traits are selected for further cultivation.

The SMARTtray® workflow automates and accelerates the plant breeding process by reducing the number of manual steps to a minimum while enabling precise and efficient sampling. The entire process from sowing to selection takes 10-14 days with SMARTtray®, depending on the plant species. Early sampling speeds up the decision-making process by 8 to 10 days compared to the traditional method.