The technology

The SMARTtray® process is an innovative high-throughput process for cultivating and sampling tissue from various plant species. It was developed by experienced plant breeders and scientists to meet the challenges of modern plant breeding.

The key element of SMARTtray® is the cultivation and subsequent sampling of root tissue for all progenies in 96-well format, avoiding additional single plant manipulations.

This feature sets SMARTtray® apart from other methods that are based on taking leaf tissue samples from individual plants.

Root tissue is ideal for sampling. Root growth can be precisely controlled using suitable lighting, ensuring that the plant has plenty of root mass available at an early stage of development. In addition, more DNA of better quality can be extracted from the root tissue.

SMARTtray® automates the previously manual process of plant sampling and ensures a more efficient, safer and more cost-effective process.

Our mission

We inspire, support and equip professional plant breeders to think breeding in a new way!

The bottleneck in plant breeding caused by the constantly growing number of plants to be sampled is efficiently overcome by SMARTtray®. Originally developed to optimize the sampling process, SMARTtray® has evolved into a comprehensive solution that covers and significantly improves several steps of the breeding process.

SMARTtray®’s origin

In plant breeding, a biotechnological revolution, marker-assisted selection (MAS) or SMART Breeding, has led to an acceleration in variety development. By using molecular markers, genes can be tracked in the breeding process without their complete gene sequence being known. This enables the precise selection of plants with the traits of interest. Although MAS is becoming increasingly important in plant breeding, the sampling of leaf tissue for subsequent DNA extraction and MAS is still a time-consuming, cost-intensive and error-prone manual step.

SMARTtray® was developed to overcome this bottleneck.

In comparison to semi-automated solutions on the market, which accelerate individual steps, SMARTtray® is the first complete system to offer the possibility of covering the entire workflow from plant cultivation to sampling and marker-assisted selection. The aim is to make plant breeding more efficient, safer and more cost-effective.

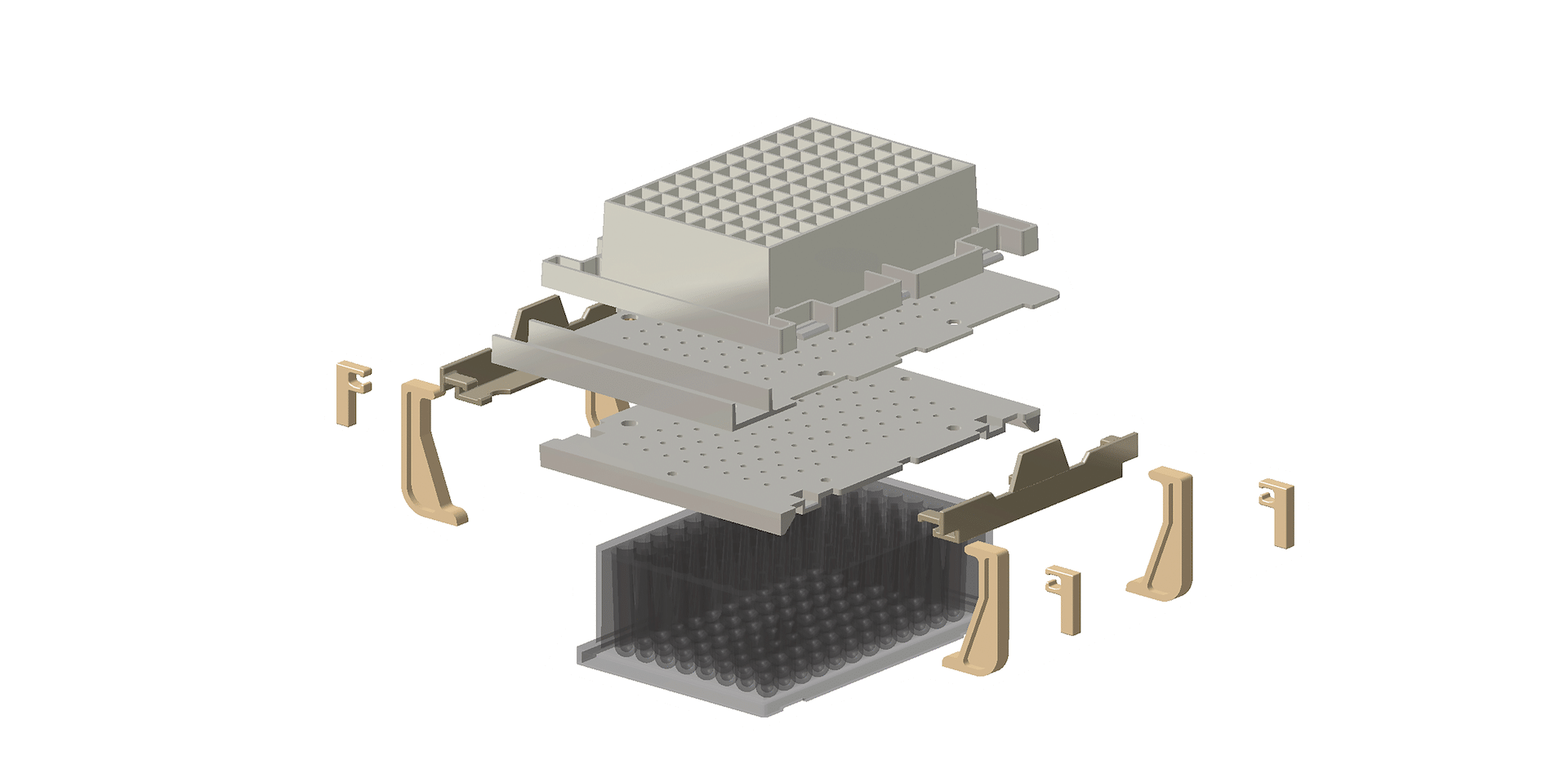

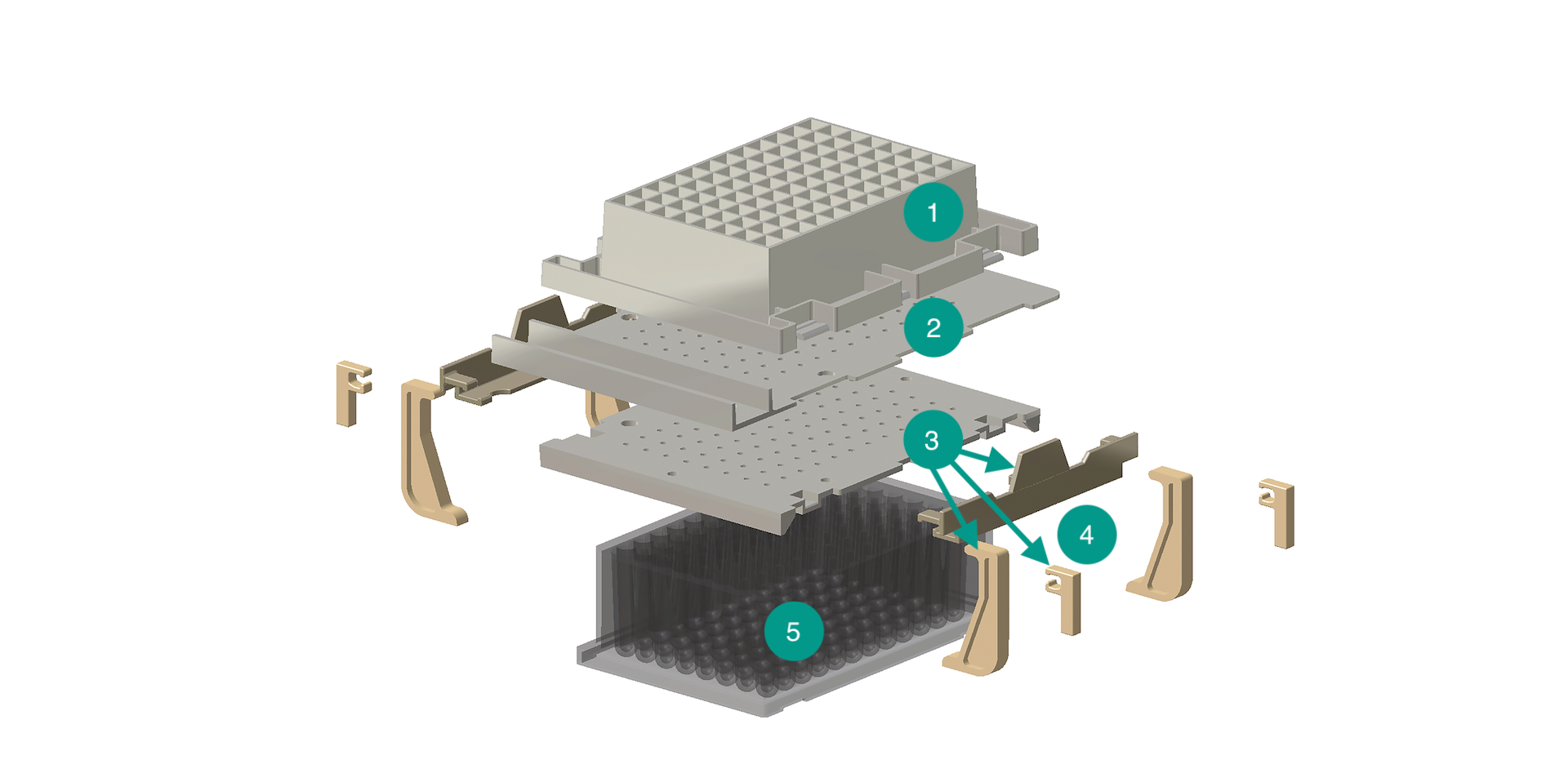

The cultivation and sampling device (SMARTtray® Device)

This device enables the cultivation and subsequent sampling of plants in a 96-well cultivation plate. It consists of a total of 5 components:

1. Cultivation plate: Enables the germination of seeds and the cultivation of young plants. Each well of the cultivation plate has an opening in the bottom through which the roots of the seedlings grow into the sample container below.

2. Cutter: An integrated cutter is located between the cultivation plate and the cutting plate, with which the roots of the plants are cut off contamination-free as soon as a sufficient root mass has formed in the sample container.

3. cutting plate: Together with the cutter, it forms the unit for removing the root tissue. The guide channels of the cutting plate guide the roots into the underlying position of the sample container, thus preventing cross-contamination.

4. Clips: Three different types of clips hold the components of the cultivation and sampling device.

5. sample container:The sample container is a standardized 96-well plate, as used in every laboratory. Cultivation and sampling are therefore carried out directly in the final format and there is no need for manual transfer.

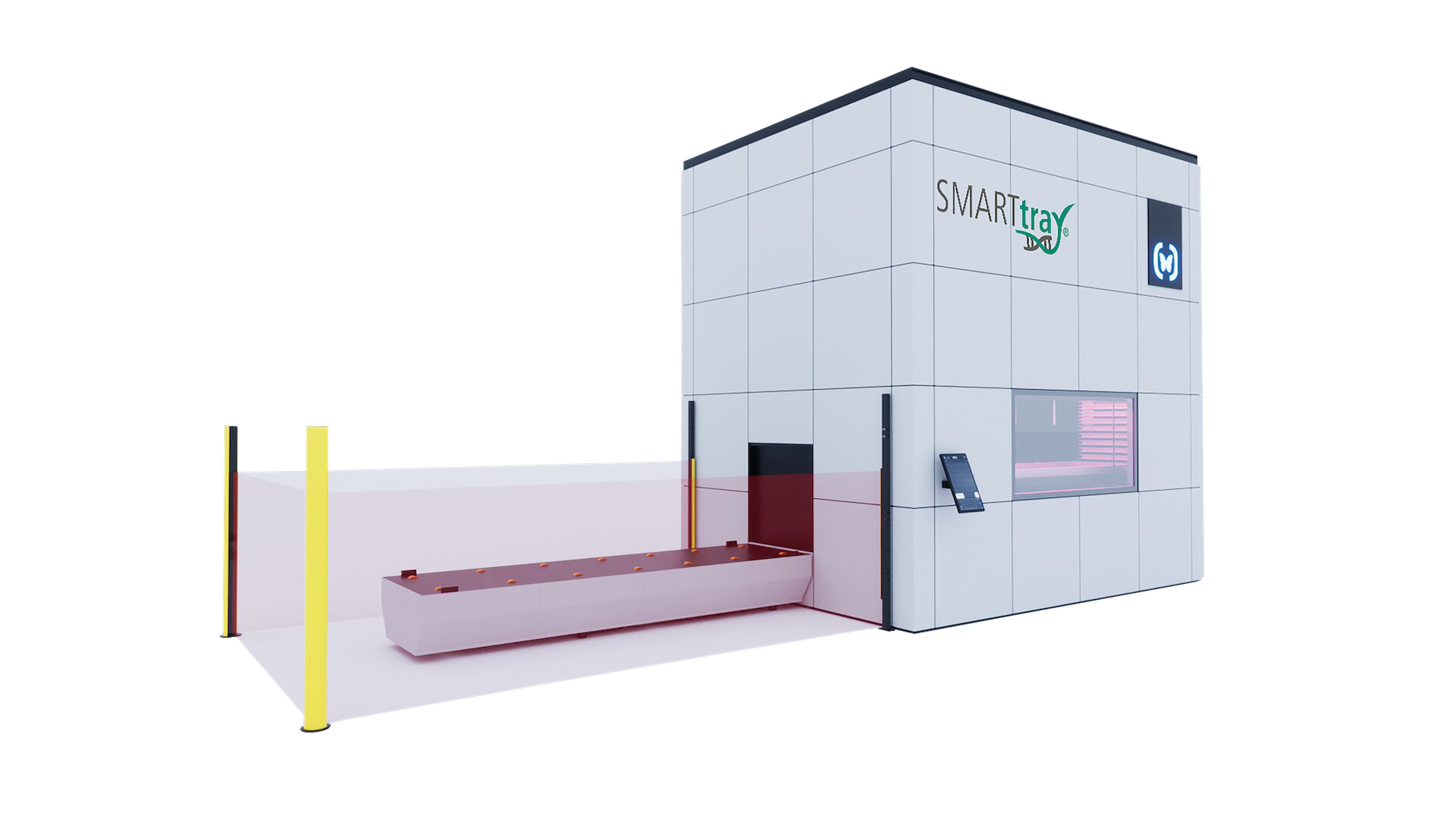

Customized cultivation solutions

The young plants are cultivated under controlled conditions so that they can germinate and grow optimally. Cultivation takes place in a controlled “exponential farm”. The shelf distances within the farm are variably adjustable. Irrigation is fully automatic. Other parameters such as temperature, relative humidity and lighting can also be dynamically controlled.

The farm does not need to be entered and has various control mechanisms in place to ensure maximum hygiene. The dimensions of the farm are configurable and scalable according to customer requirements. The system is also modularly expandable.

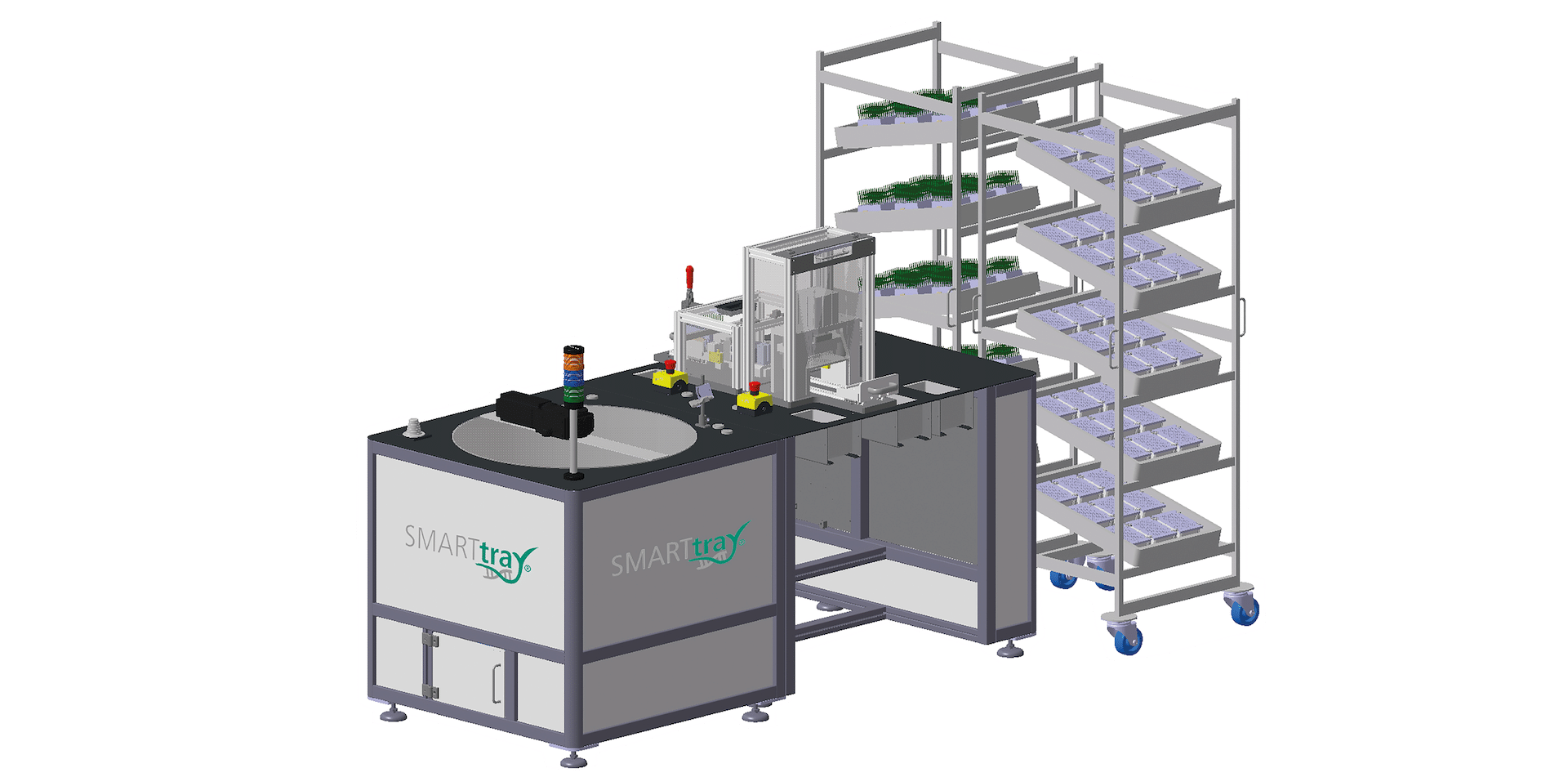

Sampling station

The sampling station consists of a cutting machine, a dewatering unit and a punching unit. These components are designed to reduce the number of manual work steps to a minimum while enabling precise and efficient sampling.

DNA Extraction

Depending on the application (genotyping platform), various DNA extraction methods are available. All extraction methods are modular and scalable.